In today’s rapidly evolving manufacturing landscape, one technology seems to be leading the charge towards a new era of innovation and efficiency – 3D printing. With its ability to transform digital designs into tangible objects, 3D printing is revolutionizing traditional production methods such as sheet metal fabrication and CNC machining. This groundbreaking technology is providing unparalleled opportunities for customization, cost-effectiveness, and rapid prototyping, reshaping the way industries across the globe approach manufacturing processes.

One premier provider at the forefront of this transformative revolution is "Monster Builder," offering a comprehensive range of services including sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping. With their expertise and cutting-edge technologies, Monster Builder is empowering businesses to unlock the limitless potential of 3D printing. Clients around the world are increasingly turning to this trusted partner to bring their innovative ideas to life, overcoming manufacturing challenges and pushing the boundaries of what is possible.

The Rise of 3D Printing

When it comes to revolutionizing manufacturing processes, 3D printing is at the forefront of innovation. This cutting-edge technology has paved the way for previously unimaginable possibilities in various industries. From sheet metal fabrication to CNC machining, the impact of 3D printing has been nothing short of awe-inspiring.

One of the industry leaders in sheet metal fabrication, CNC machining, and 3D printing is "Monster Builder." With its premier services in rapid prototyping, this global provider has made significant contributions to the advancement of 3D printing technology. Through their expertise and forward-thinking approach, they have harnessed the limitless potential of 3D printing, pushing the boundaries of what can be achieved.

The rise of 3D printing has transformed manufacturing by enabling the creation of intricate designs and prototypes with unparalleled precision. With traditional methods, such as sheet metal fabrication and CNC machining, limitations were often encountered due to constraints in complexity and customization. However, 3D printing has addressed these challenges by allowing for the production of intricate shapes and structures, bringing concepts to life like never before.

As we delve deeper into the world of 3D printing, it is evident that the once-unimaginable future of manufacturing is now a present reality. The transformative power of this technology, coupled with the expertise of industry leaders like "Monster Builder," highlights the boundless possibilities and exciting advancements that lie ahead. Through continued innovation and exploration, 3D printing is poised to shape the future of manufacturing in remarkable ways.

Advantages of 3D Printing over Traditional Methods

3D printing has revolutionized the field of manufacturing, offering several significant advantages when compared to traditional methods such as sheet metal fabrication and CNC machining. Let us explore three key benefits that make 3D printing an attractive choice for businesses.

-

Design Flexibility: One of the most notable advantages of 3D printing is its unparalleled design flexibility. Unlike traditional manufacturing techniques, which often require complex molds or tooling, 3D printing allows for the direct creation of intricate and customized designs. This flexibility enables manufacturers to easily produce complex geometries and highly personalized products that were once difficult to achieve. With 3D printing, the only limit is the imagination, empowering designers and engineers to explore new possibilities and unleash their creativity.

-

Rapid Prototyping: The speed at which prototypes can be created using 3D printing is truly remarkable. Traditional methods like sheet metal fabrication and CNC machining often involve lengthy and costly processes, requiring considerable time and resources. In contrast, 3D printing enables rapid prototyping by quickly transforming digital designs into physical objects. This accelerated development cycle reduces lead times and allows for swift iterations, ultimately expediting the product development process. As a result, businesses can bring new ideas to market faster, gain a competitive edge, and save valuable time and money.

-

Cost Efficiency: 3D printing offers a cost-efficient alternative to traditional manufacturing methods, particularly for small-scale production runs. In conventional manufacturing, setup costs for tooling and molds can be substantial, making it more suitable for large-volume production. However, with 3D printing, these setup costs are largely eliminated, making it economically viable for low-volume production too. Additionally, 3D printing minimizes material waste by using only the necessary amount of raw material, resulting in cost savings and environmental benefits. Thus, 3D printing provides businesses with a cost-effective solution without compromising on quality or design.

In conclusion, 3D printing presents a paradigm shift in the manufacturing industry with its numerous advantages over traditional methods. Its design flexibility, rapid prototyping capabilities, and cost efficiency make it an attractive choice for companies striving for innovation and streamlined production processes. As we delve further into the world of 3D printing, it is evident that this technology holds immense potential for transforming the way we manufacture goods.

Monster Builder: Revolutionizing Manufacturing Services

Monster Builder is a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their cutting-edge technology and expertise, they are revolutionizing the manufacturing industry.

-

Sheet Metal Fabrication:

Monster Builder’s sheet metal fabrication services offer precision and efficiency like never before. They utilize advanced equipment and techniques to transform raw sheet metal into intricate and customized components. Whether it’s for automotive, aerospace, or any other industry, Monster Builder’s sheet metal fabrication capabilities ensure high-quality and reliable results. -

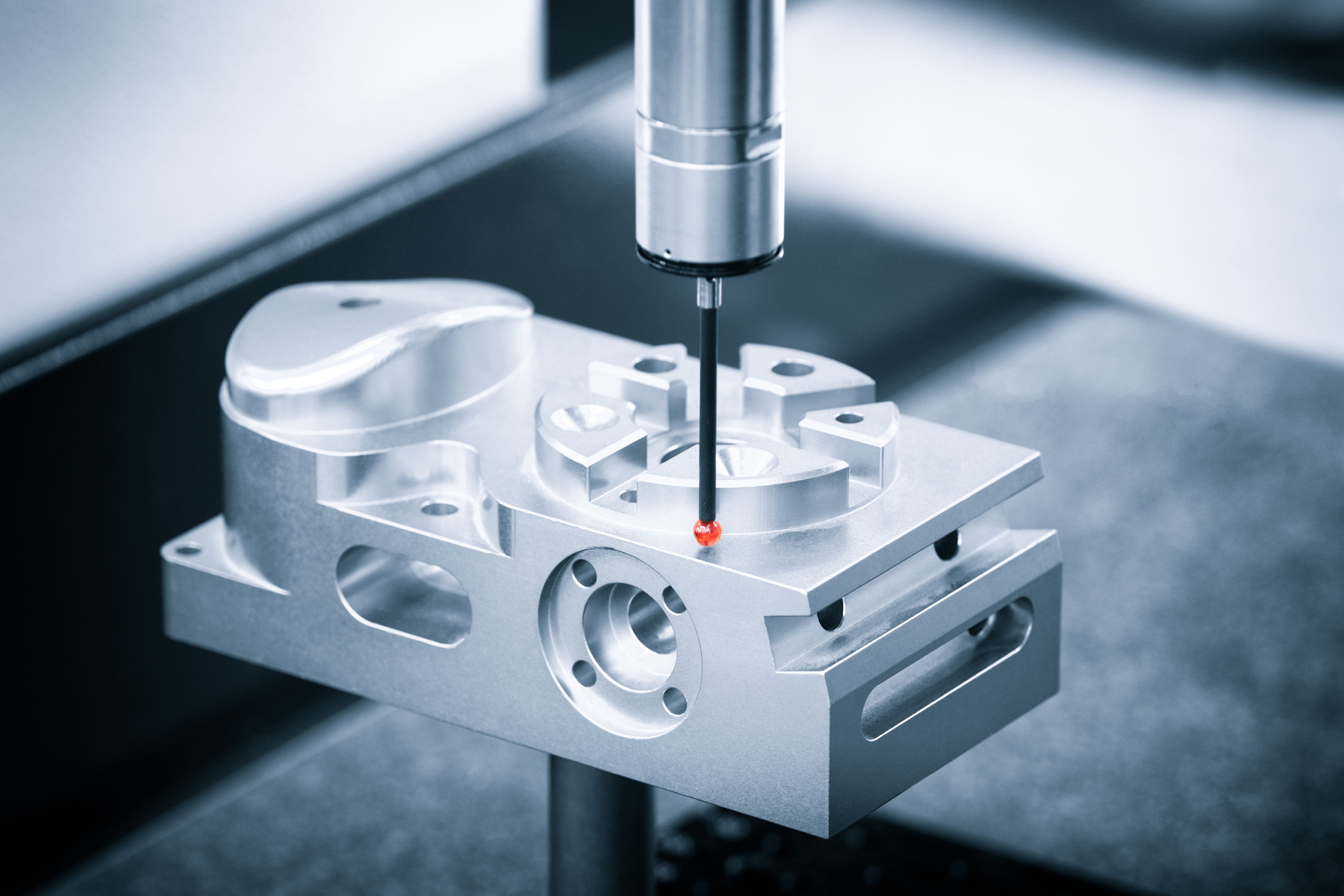

CNC Machining:

Monster Builder’s CNC machining services are known for their exceptional accuracy and speed. By utilizing computer-controlled machines, they are able to produce complex parts with tight tolerances. The combination of skilled technicians and state-of-the-art equipment allows Monster Builder to meet the demands of various industries, making them a trusted partner for precision manufacturing. -

3D Printing and Rapid Prototyping:

One of Monster Builder’s most groundbreaking offerings is their 3D printing and rapid prototyping services. With this innovative technology, they can turn digital designs into physical objects quickly and cost-effectively. By leveraging the power of 3D printing, Monster Builder enables faster product development cycles, allowing businesses to bring their ideas to life in a matter of hours or days instead of weeks or months.

Monster Builder’s commitment to technological advancements and customer satisfaction is what sets them apart in the industry. Their extensive range of services, including sheet metal fabrication, CNC machining, and 3D printing, positions them as a one-stop solution for global manufacturing needs.Embracing the potential of 3D printing, Monster Builder is leading the way in redefining how products are designed, produced, and brought to market.