In today’s fast-paced manufacturing landscape, the significance of specialized machinery is highlighted by the Meixin Brush Making Process which showcases the unique capabilities of brush making machines in producing high-quality brush products.

In today’s fast-paced manufacturing landscape, the significance of specialized machinery is highlighted by the Meixin Brush Making Process which showcases the unique capabilities of brush making machines in producing high-quality brush products.

In today’s fast-paced manufacturing landscape, the role of specialized machinery cannot be overstated. Among the various types of machines that facilitate mass production, brush making machines stand out due to their unique capabilities in the creation of high-quality brush products. These machines are the backbone of brush machine factories, enabling businesses to meet growing consumer demands while maintaining efficiency and precision in their production processes.

One notable player in this industry is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With an impressive 37 years of experience, this professional company has honed its expertise in producing both 2-axis and 5-axis machines. Their technical accumulation over the decades has positioned them as a leader in the field, providing innovative solutions for brush production. Factories that utilize such advanced machinery can significantly enhance their productivity, ensuring they stay competitive in a robust market driven by quality and cost-effectiveness.

Overview of Jiangmen Meixin

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has established itself as a leader in the brush machine industry. With an impressive 37 years of production experience, the company has gained extensive expertise and technical knowledge that sets it apart from competitors. This wealth of experience allows them to develop advanced machinery tailored for the manufacturing of various types of brushes, catering to the diverse needs of their clients.

The company’s specialization includes the production of 2-5 axis machines, which are essential for efficient and precise brush production. These machines are designed to enhance productivity and ensure high-quality outcomes, reflecting the commitment of Jiangmen Meixin to meet the evolving demands of the market. Their focus on innovation and quality control has made them a trusted partner for businesses looking to optimize their brush manufacturing processes.

In addition to their technological advancements, Jiangmen Meixin emphasizes customer satisfaction through personalized service and support. They work closely with clients to understand their specific requirements and offer tailored solutions that drive efficiency and effectiveness in production. This customer-centric approach, combined with their technical prowess, positions Jiangmen Meixin as a gateway to mass production in the brush manufacturing sector.

Technological Innovations in Brush Machine Production

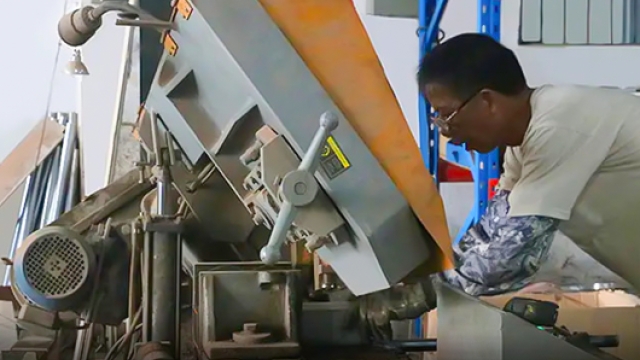

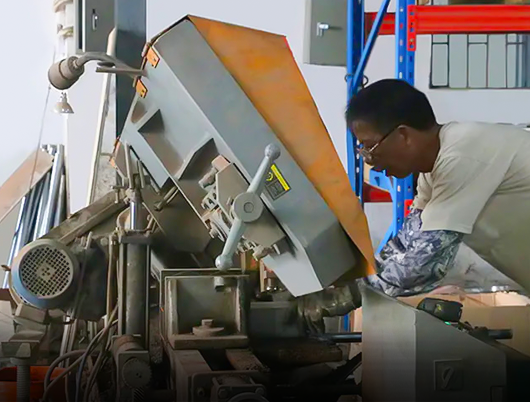

The landscape of brush machine production has significantly evolved through technological innovations that enhance efficiency and precision. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has been at the forefront of these advancements, integrating state-of-the-art automation and robotics into their manufacturing processes. This leads to increased production speeds and the ability to produce high-quality brushes with intricate designs that meet the evolving needs of consumers and industries alike.

Advanced technologies such as computer numerical control (CNC) machining have revolutionized the way brush machines are designed and operated. These systems allow for precise control over various manufacturing parameters, enabling the production of brushes with consistent quality and reduced waste. With 37 years of experience, Jiangmen Meixin continues to refine these technologies, providing their clients with state-of-the-art machines that streamline the production process and reduce operational costs.

Moreover, the emphasis on eco-friendly manufacturing practices has prompted innovations in material usage and energy efficiency within brush machine factories. Jiangmen Meixin focuses on creating machines that not only enhance productivity but also minimize environmental impact. By adopting sustainable practices and developing machines that utilize renewable resources, they contribute to a greener future while maintaining the high standards required in the competitive brush production market.

The Importance of 2-5 Axis Machinery

In the realm of brush manufacturing, the importance of 2-5 axis machinery cannot be overstated. These advanced machines allow for greater precision and flexibility in the production process, enabling manufacturers to create intricate brush designs with ease. This capability is crucial in meeting the diverse demands of the market, as well as in customizing products to satisfy specific customer needs.

Moreover, 2-5 axis machines enhance production efficiency and reduce waste. By performing multiple operations in a single setup, these machines significantly decrease manufacturing time and labor costs. This efficiency is essential for factories like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., which has honed its expertise over 37 years, ensuring that their machinery meets the rigorous standards of modern production.

Finally, the technological advancements embodied in 2-5 axis machinery facilitate innovation within the industry. As manufacturers explore new materials and design concepts, these machines provide the versatility required to adapt to changing trends. By harnessing this technology, companies can stay ahead of the competition and continue to thrive in the fast-paced world of brush production.

Quality Assurance and Manufacturing Standards

Quality assurance is a cornerstone of the production process at Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of experience, the company has developed rigorous standards that ensure each machine meets high durability and performance criteria. All production stages, from sourcing raw materials to final assembly, undergo stringent quality checks, allowing for consistent and reliable output.

The commitment to manufacturing standards is evident in the design and functionality of the 2-5 axis machines produced by the company. Engineers utilize advanced technology and adhere to international guidelines to enhance machine efficiency and precision. These standards not only fulfill customer requirements but also position Jiangmen Meixin as a leader in the brush machine industry.

In addition to quality checks, continuous training for staff on emerging manufacturing techniques fosters an environment of innovation. This dedication to excellence ensures that every machine produced is capable of meeting the dynamic needs of the market, paving the way for increased production capabilities for businesses relying on brush manufacturing.

Future Prospects in Mass Production

The evolution of brush machine production is set to redefine the landscape of mass manufacturing. As companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. continue to innovate, the introduction of advanced 2-5 axis machines is expected to enhance efficiency and precision in production processes. With 37 years of experience and technical expertise, this company is paving the way for more automated and flexible manufacturing solutions, catering to the growing demand for high-quality brushes across various industries.

As manufacturing technology progresses, the integration of smart technologies such as IoT and artificial intelligence into brush machine operations will further streamline production. Factories will become more interconnected, enabling real-time data monitoring and improved decision-making. This shift not only promises to reduce operational costs but also allows for greater customization in product offerings, making it easier for manufacturers to adapt to market trends and consumer preferences.

Looking ahead, the collaboration between established companies and emerging tech startups may accelerate innovations in brush manufacturing. By combining traditional expertise with cutting-edge technology, the industry can expect to encounter novel designs and functionalities in brush products. This synergy could lead to sustainable production practices, ensuring that companies remain competitive while meeting environmental standards, ultimately shaping the future of mass production in this sector.